ASW — your reliable bit manufacturer

ASW — your reliable bit manufacturer

Choose the right output

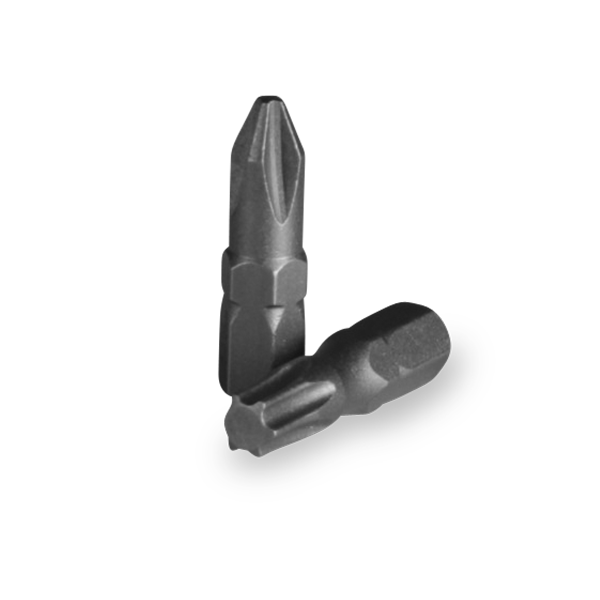

Small bits, big effect

As a bit manufacturer, we get the best possible out of our tool: power, hardness, geometry and efficiency combined in a small piece of steel. So that you achieve maximum performance with minimum effort.

Bit sets and individual tools

ASW is a manufacturer of individual bits, but has also put together various application-oriented sets that are optimized for your respective needs. The ASW range includes the most essential output drives as well as special tools so that no screw stands in your way. High quality, a special hardening process as well as a precise fit support you in mastering every construction project.

Our coatings form strong bonds with the bit, so you won’t have to deal with any noticeable wear. To ensure hardness and stability, we also regularly carry out our own tests.

ASW: The bit manufacturer with know-how

As a bit manufacturer, we also deal with the difficulties you encounter in your everyday work:

- No cam-out effect: Slipping of the bits out of the screws is greatly reduced.

- Drives: Our range is designed to fit your needs — for example, choose an E6.3 drive to gain more holding power with the help of the ball in the bit holder.

- Breakage: Our bits, in sets or individually, cushion — through precisely calculated zones in the bit geometry — slight twisting and therefore only break under disproportionate loads.

- Processing: We make sure that the production of our bits is constantly monitored and optimized. We test all manufactured tools with standard test gauges.