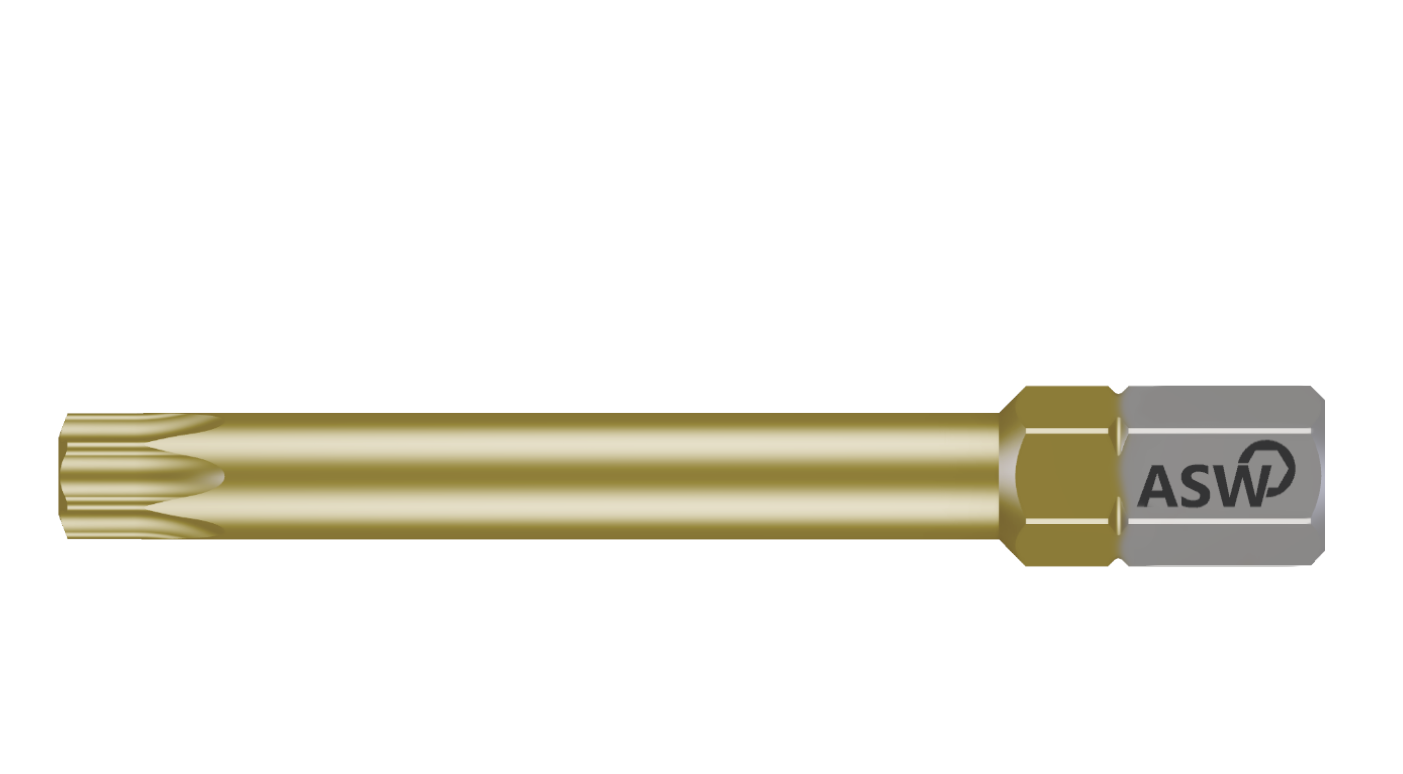

Bits for TORX® screws

ASW Wekador Bits for TORX® screws

Call? E‑mail? Contact form? Whichever route you choose, we will be happy to advise you free of charge.

Game Over for the Cam Out Effect

With bits for TORX® screws you save time, power and nerves — because the profile not only transmits much higher torques than slotted or cross-slotted bits, but also reduces the cam-out effect. So you get ultimate power without any stress — for easy working days and fun in the home workshop.

Bits and sockets for TORX® screws — external and internal

Bits for TORX® screws have a hexagon socket drive which, unlike cross-slotted bits, is not tapered but has six parallel flanks. Due to the lack of axial force, they do not simply slip out of the screws.

Because the rotational forces are not only applied selectively, but to the entire flanks, even more power can be transmitted — with even less wear.

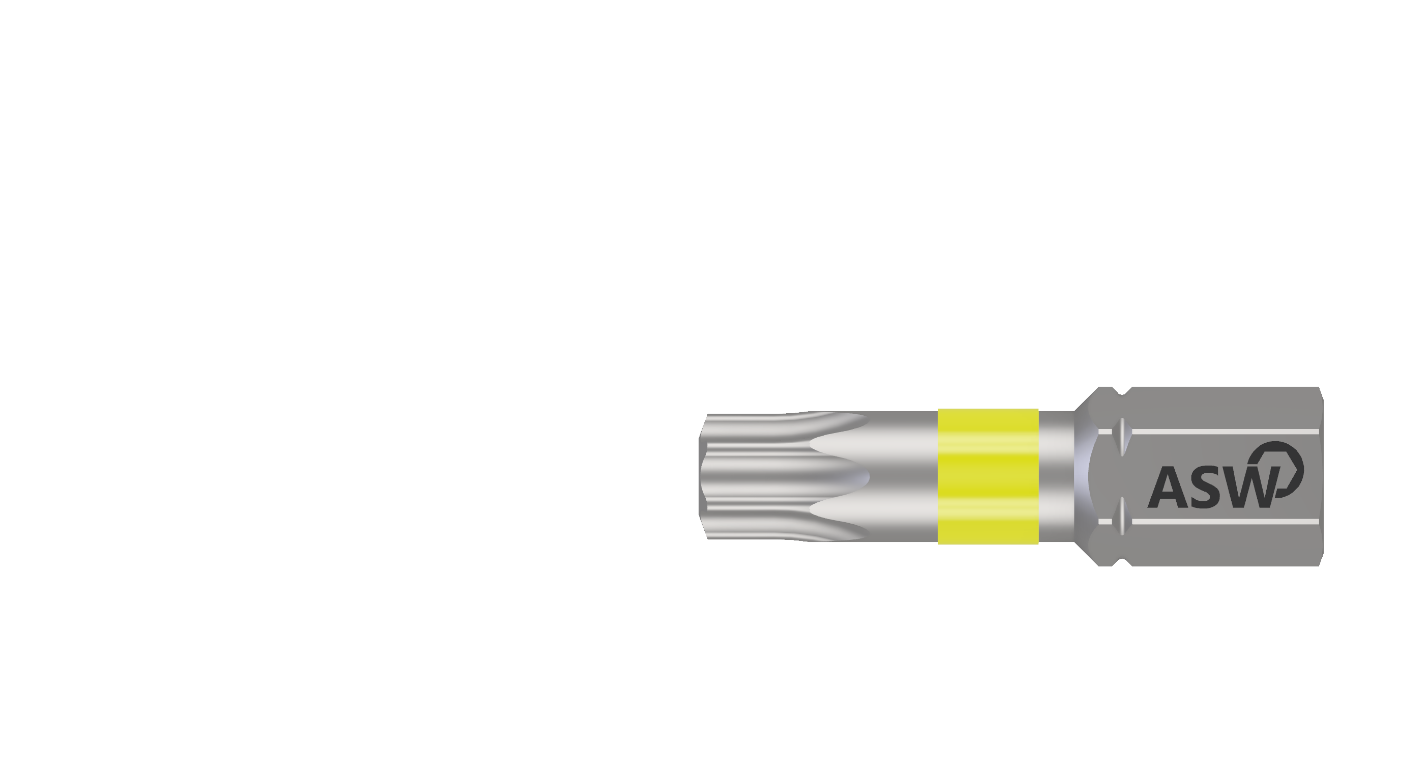

There are different variants of TORX® drive bits: Bits for inside and outside TORX® screws, as well as the TR (Tamper-Resistant) range, where a small pin in the middle of the screw prevents anyone who does not have the right tool from loosening it. We also produce differently coated bits that further support the quality of our materials.

Bits for TORX® screws for efficient power transmission

Bits for TORX® screws have a variety of advantages, especially compared to more familiar drivers such as slotted, PH or PZ:

- Low-wear: The profile is gentle on screw and bit. That is why they are also suitable for automatic production with the help of robots, for example.

- In general, the more flanks, the easier it is for the bit to find its way into the screw. That is why the TX drive is particularly fast and efficient.

- Power-saving: If you work with cordless screwdrivers, speed is synonymous with longer battery life.